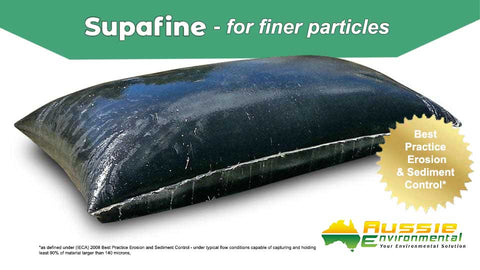

Silt Fence Filter Kit

Silt Fence Filter Kits are categorised as a Type 2 Sediment Trap which have been designed to adhere to IEACA Best Practice Guidelines (2008). Kits have extra treatment requirements as detailed in the Queensland State Planning Policy (2017). Silt Fence Filter Kits are easy to install and a cheaper alternative to traditional Type 2 sediment traps.

You’re Covered By Our 14-Day Money-Back Guarantee

Worried about ordering online? Afraid of getting the wrong product? Our certified erosion and sediment control experts work tirelessly to ensure you get the right product for your needs, the first time around. But just in case, we also protect you with our 14-day money-back guarantee!

If you don’t like your product, simply send it back to us in an unused and resalable condition in 14 days. We’ll refund you every cent you paid, no questions asked!

Customer Reviews

Queensland’s Largest Supplier Of Direct-To-Consumer Environmental Products

If you can’t find the right solution at Aussie Environmental, chances are it doesn’t exist! We only provide the highest quality products across our enormous range… and we import nearly all of them ourselves. That means you’ll get a reliable solution that makes light work of your issue… and you’ll get it for a crazy, direct-to-consumer price!

-

15+ Years Experience

-

The Largest Range Of Environmental Control Products

Affordable Freight And Shipping To Anywhere In Australia

As an Aussie owned and operated company, we want to serve our country right. That’s why we provide affordable freight and shipping Australia-wide. In the unlikely event you’re unhappy with your freight cost, simply get in touch with our friendly team. We’ll see if we can find you a better option, to get your product delivered on time and on budget!

-

Independently Imported

-

US Standard Products

Why We’re Your Best Bet For Environmental, Erosion, And Sediment Control…

| Features |  |

The Rest |

|---|---|---|

| Largest Product Range In Queensland | Yes | No |

| Exclusive Supplier Of Select Products | Yes | No |

| Shipping Australia Wide | Yes | Sometimes |

| Direct-To-Consumer Prices | Yes | No |

| High Quality, Sustainable Products | Yes | Sometimes |

| Recommendations From Certified Experts | Yes | No |

| Australian Owned And Operated | Yes | Sometimes |

| 14-Day Money-Back Guarantee | Yes | No |

| 10% Off Your First Order | Yes | No |